Variable Frequency Temperature Control Dehumidifier for Food Industry Workshops

2025-11-10

The dew point can reach as low as 3°C, w...

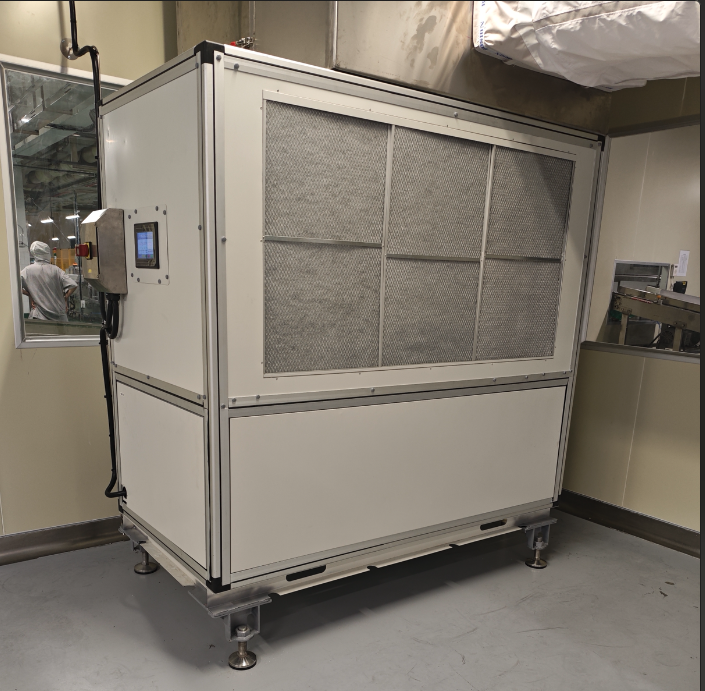

Biscuit Production Workshop Climate Control and Industrial Dehumidification System Project Introduction

[Project Overview]

This project provides a customized industrial climate solution for the biscuit production workshop, offering precise temperature and humidity control for an 800㎡ production area. The project utilizes advanced energy and efficiency technologies, replacing traditional high-energy consumption desiccant wheel dehumidifiers to achieve efficient and energy-saving industrial dehumidification and accurate humidity control.

Core project parameters:

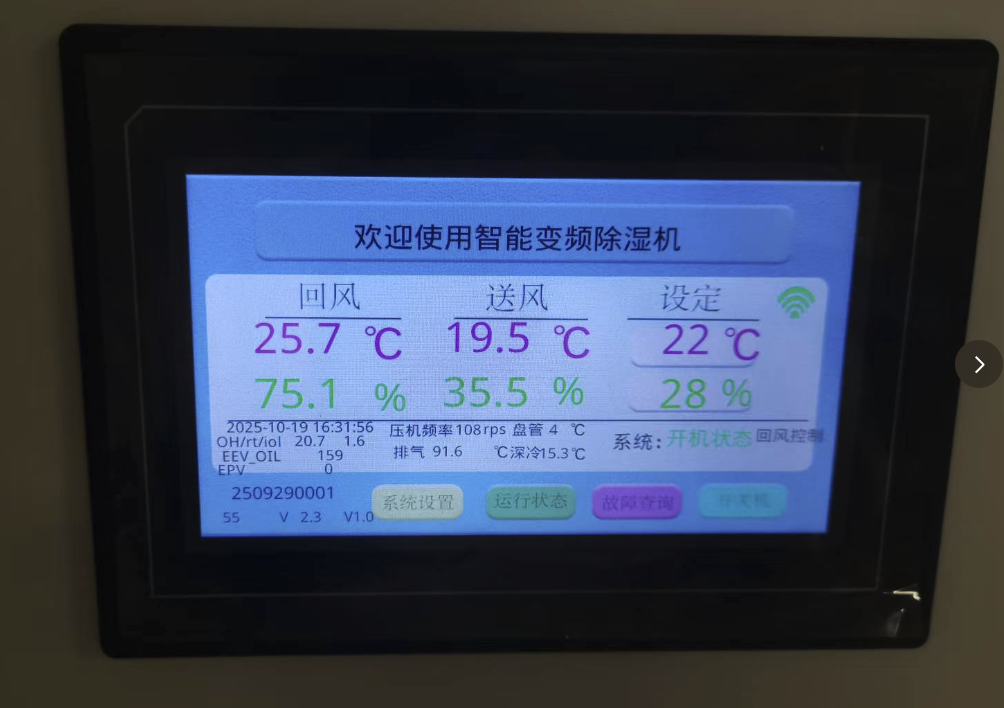

- Control requirements: Temperature 24℃ ±1℃, Humidity 45% RH ±3%

- Low dew point air supply: Minimum dew point can reach 3℃, air moisture content is only 5g/kg dry air

- Application area: 800 square meters

- Application scenario: Food plant dehumidification

- Equipment type: Clean room dehumidifier

- Control standard: Industrial dehumidification system standards

[Core Technical Advantages]

1. Low Dew Point Air Supply Technology

The core advantage of this system lies in its low dew point air supply technology, enabling deep dehumidification with a minimum dew point of 3℃. This technological breakthrough allows the supplied air's moisture content to be only 5g/kg dry air, far exceeding the dehumidification capacity of traditional equipment. Technical features include:

- Minimum dew point reachable at 3℃, achieving deep dehumidification

- Air moisture content as low as 5g/kg dry air, meeting high-standard process requirements

- Ultra-low dew point ensures product quality, preventing moisture absorption and dampness

- Suitable for high-demand scenarios such as dry room dehumidification

2. Evaporative Cooling Technology

Utilizing an innovative evaporative cooling working principle, it significantly reduces compressor energy consumption through evaporative cooling media. Combined with low dew point air supply technology, the use of an evaporative cooling system can achieve a Coefficient of Performance (COP) as high as 5.4, realizing:

- Significant reduction in compressor load

- Decreased energy consumption costs

- Enhanced overall operational efficiency

3. Variable Frequency Regulation Technology

Integrating dual variable frequency technologies of variable frequency debugging compressors and variable frequency regulating fans, it achieves:

- Precise temperature and humidity control

- Automatic load adjustment

- Energy saving, cost reduction, and efficiency improvement

4. Intelligent Climate Control System

Equipped with an advanced climate controller, supporting:

- Automated climate control

- Real-time temperature and humidity monitoring

- Online humidity monitoring

- Precise adjustment with a humidistat

[Detailed Equipment Configuration]

1. Air Handling Unit

This system employs a desiccant air handling unit design, integrating:

- Air heat exchanger - efficient heat exchange

- Industrial air to air heat exchanger

- Heat exchanger air vent - optimized airflow distribution

2. Water Cooling System

Utilizing a water evaporation cooling system, ensuring:

- Efficient cooling distribution

- Stable operating temperature

- Reduced operational costs

3. Dehumidification Unit

Dedicated dehumidification system, including:

- Efficient dehumidifier humidity control

- Precise control of moisture

- Application of moisture eliminators technology

[Multiple Operation Modes]

This system supports three professional dehumidification modes to meet different working condition needs:

1. Cooling Dehumidification Mode

Standard operation mode in high temperature and high humidity environments, achieving rapid temperature and humidity reduction through evaporative cooling.

2. Heating Dehumidification Mode

Suitable for low temperature and high humidity environments, integrated with an industrial air heater to ensure stable production conditions.

3. Isenthalpic Dehumidification Mode

Precisely controlled via a psychrometric calculator, achieving constant temperature dehumidification and optimizing energy utilization.

The system includes built-in online psychrometric charts and interactive psychrometric charts, supporting online humidity measurement and real-time humidity calculations.

[Application Advantages]

1. Specialized for the Food Industry

- Complies with clean room humidity control standards

- Meets food plant dehumidification requirements

- Ensures food safety and hygiene standards

2. Industrial-grade Dehumidification

- Industrial dehumidification systems

- Technology from industrial dehumidifier manufacturers

- Performance of efficient dehumidifiers

3. Energy Saving and Emission Reduction

Applying advanced abatement technology, achieving:

- Replacement of traditional high-energy rotary dehumidifiers

- Significant reduction in carbon emissions

- Active response to environmental policies

4. Intelligent Control

- Humidity control systems

- Humidity control services

- Humidity control solutions

[Technological Innovation Points]

1. Breakthrough in Ultra-low Dew Point Technology

Innovative low dew point air supply technology achieves deep dehumidification capability at a 3℃ dew point, reducing air moisture content to 5g/kg dry air. This breakthrough enables the system to meet extremely demanding dry room solutions, applicable to scenarios highly sensitive to humidity like battery manufacturing dry rooms and food production.

2. Optimization of Evaporative Cooling Media

Utilizing professional evaporative cooling media and evaporative cooler media to enhance cooling efficiency.

3. Air Distribution Optimization

Through the design of cooling distribution units, ensuring uniform temperature and humidity distribution within the workshop.

4. Humidity Monitoring System

Integrated with online psychrometers and mixed air temperature calculators for accurate monitoring.

5. Humidity Calculation Software

Equipped with psychrometric chart programs and psychrometric chart calculators, supporting precise calculations.

[Project Value]

Economic Benefits

- Over 50% energy saving compared to traditional rotary dehumidifiers

- COP as high as 5.4, significantly reducing operating costs

- Variable frequency technology enables on-demand adjustment, reducing无效 energy consumption

Product Quality Improvement

- Precise and stable temperature and humidity control increases product yield

- 3℃ low dew point air supply effectively prevents product moisture absorption and dampness

- Ultra-low moisture content of 5g/kg dry air ensures product quality

- Reduces product quality issues caused by environmental fluctuations

- Guarantees biscuit quality stability

Environmental Benefits

- Application of Energy and Efficiency Technologies

- Abatement system aids in carbon neutrality

- Complies with green production standards

Industry Benchmark

- Leading application of Industrial Climate Solutions

- Technological innovation in Humidity-Control Products

- Provides a standard demonstration case for the food industry

[Equipment Manufacturer Qualifications]

This system is designed and manufactured by a professional industrial dehumidifier manufacturer, employing:

- Mature technology of commercial desiccant dehumidifiers

- Standards of commercial dehumidification systems

- Quality assurance of industrial dehumidification products

The system supports standalone dehumidifier operation modes and can also be integrated into existing ventilation solutions.

[Summary]

This project utilizes innovative low dew point air supply technology, evaporative cooling technology, and advanced energy and efficiency technologies to provide a professional industrial climate solution for the biscuit workshop. The system not only achieves ultra-low moisture content control with a minimum dew point of 3℃ and 5g/kg dry air but also demonstrates significant results in energy saving, cost reduction, product quality improvement, and environmental emission reduction.

Compared to traditional rotary dehumidifiers, this system has achieved technological breakthroughs in ultra-low dew point dehumidification, COP improvement, operational stability, and intelligent control, setting a new industry benchmark for industrial dehumidification applications in the food industry.

The successful application of the project demonstrates the great potential of low dew point air supply technology and evaporative cooling technology in the field of industrial dehumidification, providing valuable experience and technical reference for the promotion and application of similar high-demand dehumidification projects.

[Keyword Index]

Purified Air | Humidity Control | Industrial Dehumidification | Evaporative Cooling | Climate Controller | Air Handling Unit |

Low Dew Point Air Supply | 3℃ Dew Point Dehumidification | Clean Room Dehumidification | Variable Frequency Regulation | Energy-saving Technology | Food Plant Dehumidification |

Dry Room Dehumidification | Dehumidification System | Efficient Dehumidifier | Humidity Control Services | Online Humidity Monitoring |

Intelligent Climate Control | Abatement Technology | Industrial Climate Solutions | Dry Room Design