Citric acid food additive fluidized bed dryer variable frequency fresh air dehumidification equipment

2026-02-04

The fluidized bed dryer prevents powder ...

Variable Frequency Fresh Air Dehumidification Equipment for Fluidized Bed Applications

A fluidized bed dryer is a device commonly used in the industrial drying field, utilizing the principle of gas-solid fluidization to rapidly dry wet materials. The following are the principles of the fluidized bed dryer and the characteristics of its fresh air requirements:

Principles of Fluidized Bed Dryer:

Wet Material Feeding: Wet material enters the fluidized bed dryer through the feeding system.

Gas Feeding: Hot air or other hot medium is injected into the dryer, causing the gas-solid mixture within the bed to be in a fluidized state.

Wet Material Drying: The wet material contacts the hot air in the fluidized bed, moisture is carried away by the hot air, and the material gradually dries.

Dried Material Discharge: The dried material is discharged from the fluidized bed dryer through the discharge system.

Characteristics of Fresh Air Requirements:

Drying Medium: Fluidized bed dryers typically use hot air or other hot media as the drying medium, requiring sufficient fresh air supply for the drying process. The fresh air demand is related to factors such as material moisture content, drying temperature, and drying rate.

Temperature Control: The drying process requires controlling the temperature of the hot medium to ensure the material dries within a suitable temperature range. One characteristic of fresh air demand is the need to provide sufficient hot air volume and regulate the temperature inside the dryer by controlling the hot air temperature.

Humidity Control: Fresh air demand is also related to the discharge of moist air after drying. The moist air inside the dryer needs to be discharged and treated (e.g., condensation, dehumidification, etc.) before being released or recycled.

Recirculated Air: Fluidized bed dryers often recycle a portion of the dried hot air to re-enter the bed for drying, improving thermal efficiency and saving energy. A reasonable balance and control between recirculated air and fresh air demand are necessary.

The specific drying process and requirements determine the characteristics of fresh air demand for a fluidized bed dryer. Different material properties, humidity requirements, and drying temperatures, among other factors, will have a decisive effect on product quality.

Case Study:

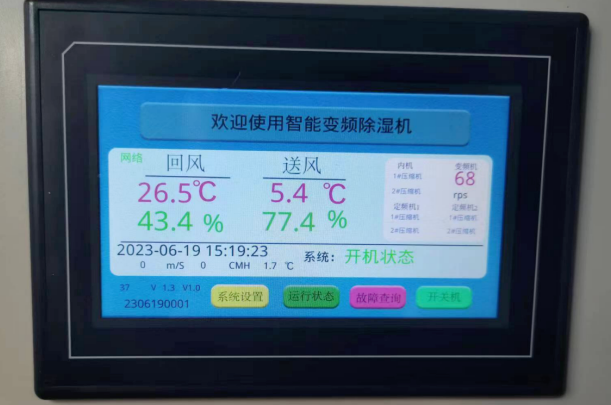

Project Name:Fresh Air Dehumidification Equipment for a Food-grade Fluidized Bed in Huangpu District, Guangzhou

Air Demand: 1800-6000CMH air volume, 6-8g water outlet

Project Outcome:

Stably supplies air at 1-2°C dew point, with supply air moisture content around 4g;

Most vulcanization industries require air with an absolute humidity of 6-8g water per kg of air, a demand currently primarily met by desiccant wheel dehumidifiers in the market. However, our company's newly developed variable frequency fresh air dehumidifier can process the dew point temperature down to 1-2°C (4g moisture content), and its energy consumption is significantly lower than traditional desiccant wheel dehumidifiers.

This technological innovation holds great potential. By processing the dew point temperature to such a low level, our dehumidifier can more effectively remove moisture from the air entering the system, meeting the stringent requirements of the vulcanization industry for high-humidity environments. At the same time, low energy consumption is a key advantage of our product, not only reducing operating costs but also improving energy efficiency.

To ensure product reliability, we have conducted sufficient experiments and tests. A comprehensive performance comparison with desiccant wheel dehumidifiers on the market has proven that our product indeed excels in terms of energy consumption and performance. This innovation will attract the attention of more users and customers.

In summary, our variable frequency fresh air dehumidifier has broad application prospects in the vulcanization industry. Its excellent performance and low energy consumption will bring business opportunities and competitive advantages to our company.