Laboratory high-precision variable frequency constant temperature and humidity air conditioner

2026-02-04

Using a genetic control algorithm, the t...

I. Project Overview

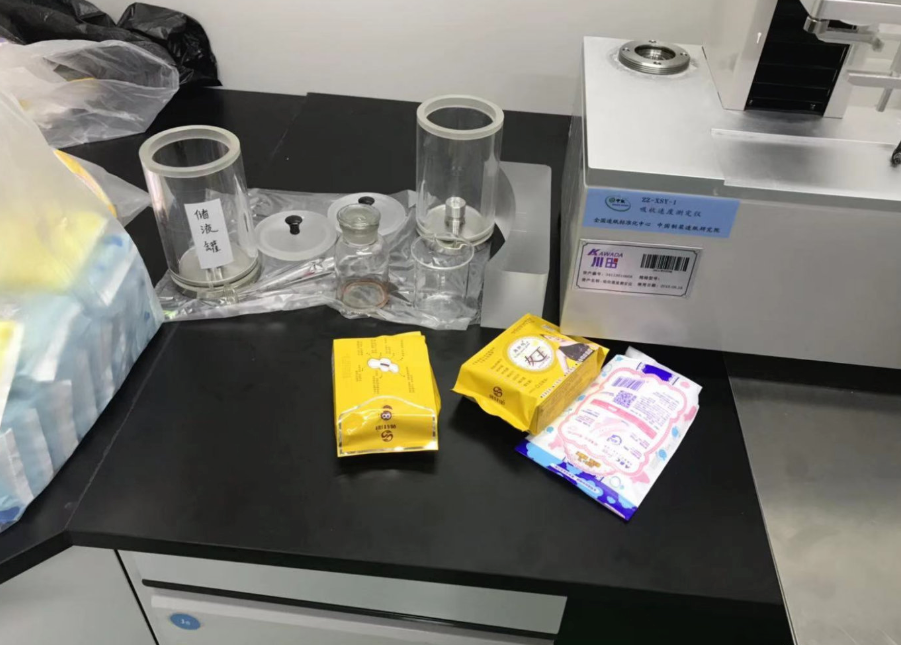

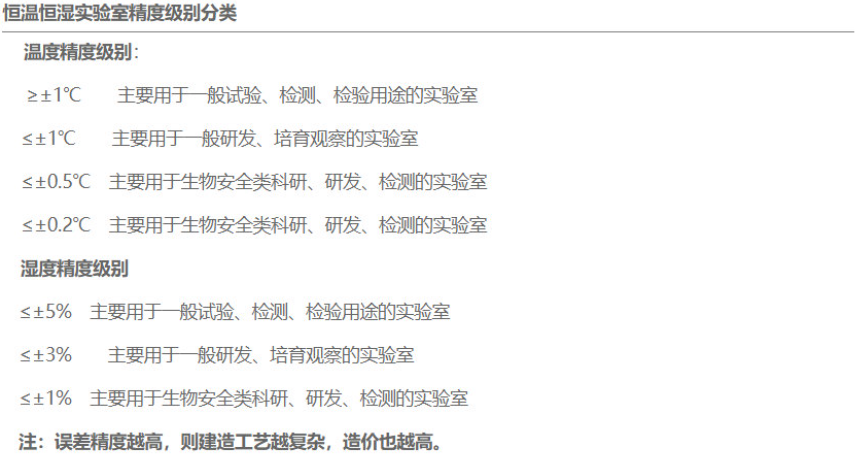

This project is for the sanitary napkin filler laboratory of the Japanese-funded Kawada company. The initial contractor selected equipment from another manufacturer, which lacked precision control technology, resulting in the project's inability to meet the agreed control accuracy of 23±1°C, 50±2%. After the customer switched to our company's equipment, the high-precision requirements of 23±0.2°C, 50±1% were ultimately achieved.

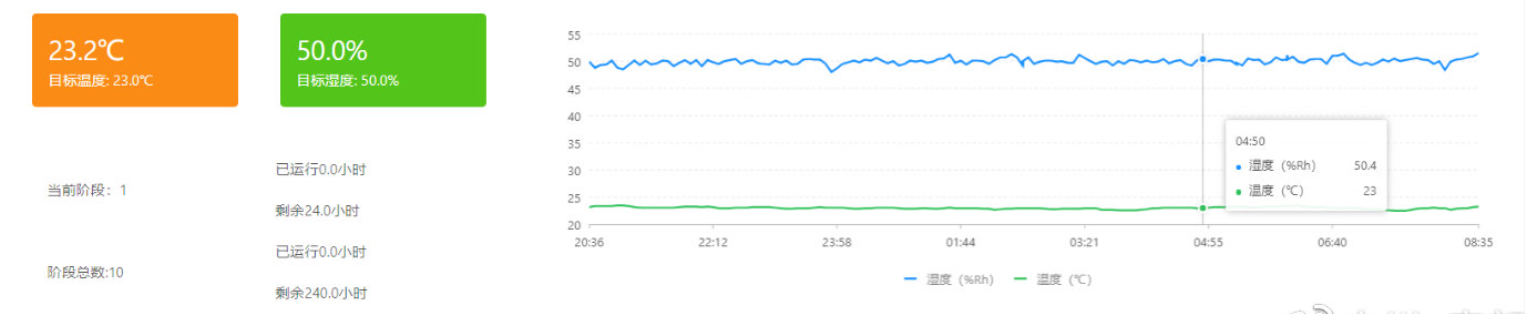

Data collected via the Internet of Things shows that the laboratory accuracy reached the high precision of 23±0.2°C, 50±1%.

Basically meets the usage requirements for biotechnology research and development

II. Application of Genetic Algorithm in Control Strategy

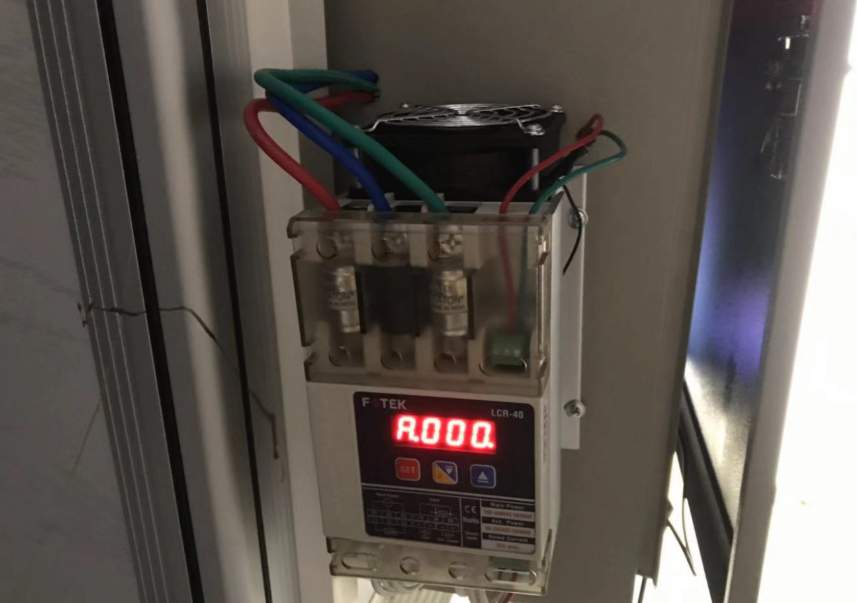

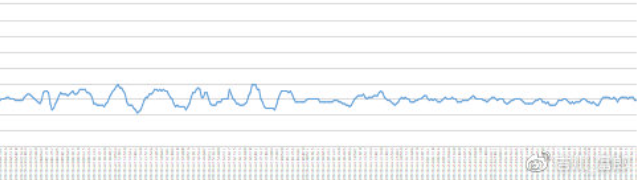

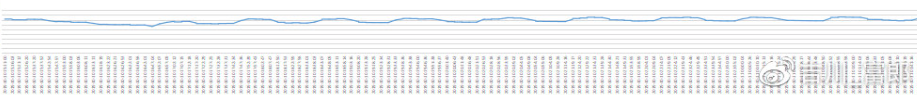

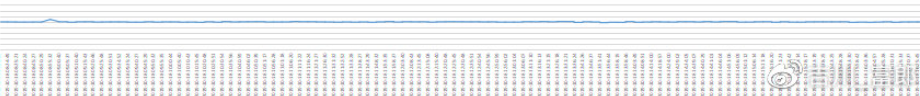

This project primarily involved inserting a genetic algorithm into the traditional PID algorithm, utilizing an internal FPGA chip for high-speed computation, ultimately evolving stable parameters. Captured curve data from the evolution process:

Evolution process of indoor temperature, showing the continuous narrowing of oscillation amplitude.

Evolution process of indoor humidity

Initial large fluctuations

Subsequent trend towards stabilization

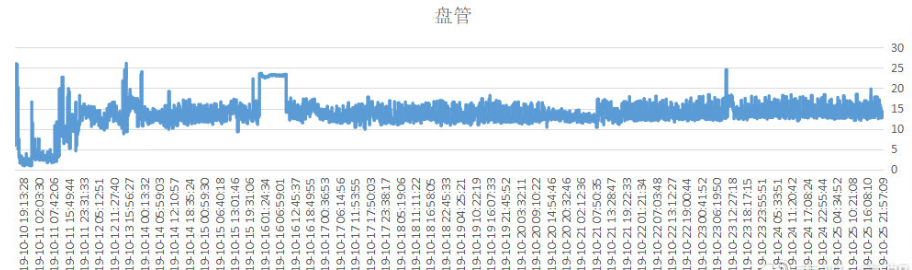

Excellent coil data, mostly above 0 degrees, whereas some manufacturers' equipment suffers from severe icing.

Project Images