Ultra-low temperature variable frequency water chiller

2024-06-18

Low-temperature freezing technology, inverter compressor, maintains stable low-temperature operation. ...

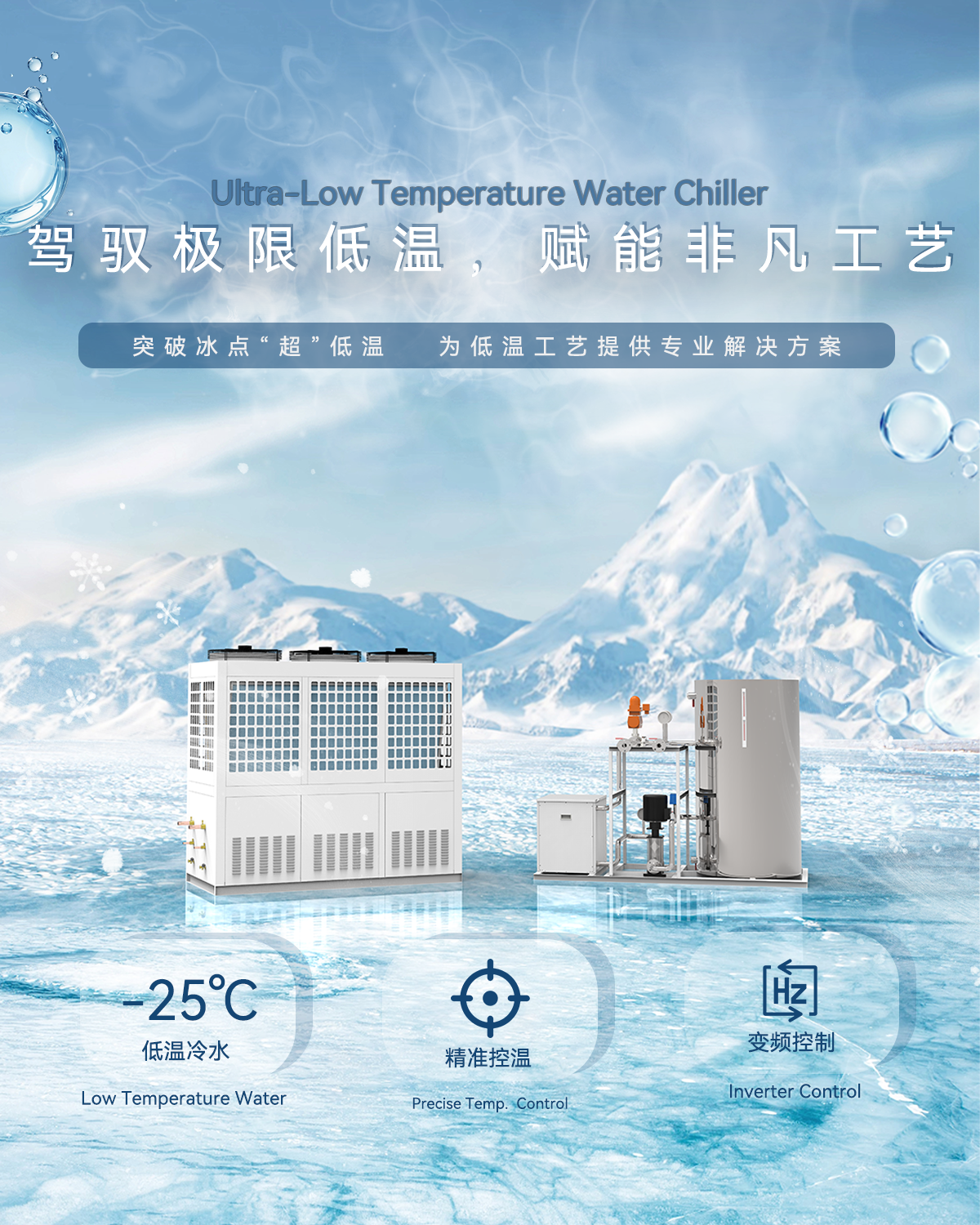

Ultra-Low Temperature Inverter Chiller

· Product Overview

The Ultra-Low Temperature Chiller is a device specifically designed for low-temperature processes, with its core capability being the stable output of -25℃ water temperature (a mixture of pure water and antifreeze). It provides an efficient and reliable cold source for industrial fields requiring deep refrigeration.

· Product Technology

-

Air Source Heat Pump Principle: The unit uses the heat from the ambient air as a low-temperature heat source, driven by electrical energy, and utilizes the work of the compressor to continuously transfer the heat absorbed by the refrigerant at the evaporator to the condenser for release.

-

Deep Refrigeration and Anti-freezing: On the evaporator side, the unit creates an evaporation environment far below 0℃ through special low-temperature refrigerants and system design. The coolant flowing through the evaporator (typically a mixture of water and antifreeze like glycol) is cooled to the target temperature (e.g., -25℃). The added antifreeze effectively prevents the liquid from freezing at extremely low temperatures, ensuring safe and stable operation of the system under sub-zero conditions.

-

Inverter Technology: Unlike traditional fixed-frequency technology, the compressor does not stop but shifts to low-speed operation, just enough to "offset" the thermal or humidity load from the environment, thereby maintaining an extremely stable state. Inverter technology is not only an energy-saving technology but also a comprehensive solution that enhances equipment performance, reliability, and user experience through precise control.

· Application Scenarios

This unit is an ideal choice for the following industrial fields that require deep refrigeration and precise temperature control:

-

Chemical and Pharmaceutical: Reactor cooling, crystallization processes, material condensation recovery, vacuum freeze-drying.

-

Food Processing: Quick freezing, low-temperature tunnels, ice cream production, rapid food cooling.

-

Laboratory and Scientific Research: Low-temperature material testing, environmental simulation chambers, semiconductor testing, cooling of scientific instruments.

-

Special Industries: Lithium battery production, laser cooling, rapid cooling for plastic machinery (such as injection molding).

· Product Parameters

Product Model: NUXCDW-50HP

Cooling Capacity: 30KW(-25C/-30°C) 42KW(-20C/-25) 53KW(-10℃C/-15)

Refrigerant: R410A

Rated Power: 50KW

Power Input: 380V/50HZ Three-phase five-wire system

Compressor: Copeland

Water Temperature: 15℃~-30℃

Auxiliary Electric Heating: 13.5KW(3 sets)